Revolutionizing Industrial Automation with Electric Conveyor Belts

The Early Days of Conveyor Systems

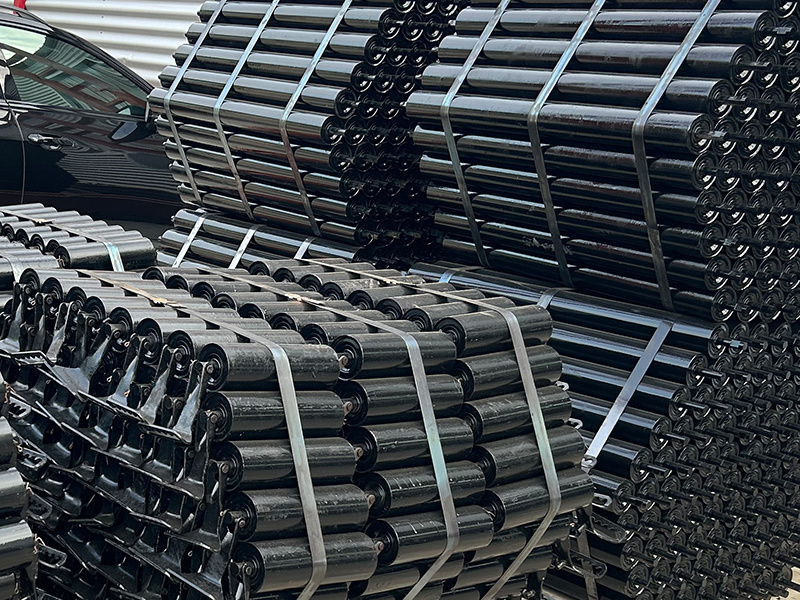

In the late 19th century, the first conveyor systems were introduced as a way to streamline production processes in factories. These early systems consisted of simple roller conveyors that were manually operated by workers. While primitive by today's standards, these early conveyors were a significant improvement over manual transportation methods, allowing for faster and more efficient movement of materials.

The Rise of Automated Conveyor Systems

As technology advanced, so did conveyor systems. In the mid-20th century, automated conveyor systems began to emerge, incorporating motors and sensors to automate the movement of materials. These systems revolutionized the manufacturing industry, increasing efficiency and productivity in factories around the world. Automated conveyor systems allowed for continuous, uninterrupted production lines, leading to significant cost savings for manufacturers.

Innovations in Conveyor Technology

In recent years, advancements in technology have led to the development of highly sophisticated conveyor systems. Modern conveyors are equipped with state-of-the-art features such as RFID tracking, automated sorting, and dynamic routing capabilities. These innovations have further improved the efficiency and reliability of conveyor systems, making them essential components of modern manufacturing facilities.

The Future of Industrial Conveyor Systems

Looking ahead, the future of industrial conveyor systems is filled with exciting possibilities. As technology continues to evolve, we can expect to see even more advanced conveyor systems that are faster, smarter, and more adaptable to changing production demands. From AI-powered systems to self-driving conveyors, the future holds endless opportunities for innovation in the world of industrial automation.

Conclusion

The evolution of industrial conveyor systems has been a remarkable journey, transforming the way materials are transported within factories and warehouses. From humble beginnings to cutting-edge technology, these systems have revolutionized the manufacturing industry and continue to play a vital role in modern production processes. As we look to the future, the possibilities for innovation in conveyor technology are limitless, promising exciting advancements that will further enhance efficiency and productivity in manufacturing facilities around the world.

Keywords:

Previous

Previous:

Latest News

Why do PVC conveyor belts need to be wrapped?