- Description

-

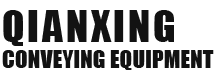

Electromagnetic separators are electromagnetic devices specifically designed to remove ferrous materials from bulk non-magnetic materials. They are widely used in power, mining, metallurgy, building materials, coal preparation, and chemical industries. Below is a detailed introduction to electromagnetic separators:

Working Principle

The working principle of an electromagnetic separator is based on electromagnetic induction and the properties of magnetic materials. It contains a coil, usually wound around an iron core. When energized, the coil generates a strong magnetic field within the iron core. This magnetic field attracts ferromagnetic impurities, separating them from the processed material.

Main Structure: Electromagnetic separators mainly consist of a casing, electromagnetic coil, iron core, magnetic pole filling material, and junction box.

Working Process

1. Energization: The power supply system is connected to the energized coil to provide the required electrical energy. The energized coil typically consists of numerous insulated wires wound into a dense coil.

2. Magnetic Field Generation: When current flows through the energized coil, a powerful magnetic field is generated around the coil. This magnetic field can be used to attract ferromagnetic impurities.

3. Adsorption of Ferromagnetic Impurities: When materials pass through the electromagnetic separator, if they contain ferromagnetic impurities, these impurities will be attracted by the magnetic field. This is because ferromagnetic impurities have a high magnetic permeability and are subjected to a greater attractive force in a strong magnetic field[^2^]. Applications Electromagnetic separators are widely used in the power, mining, metallurgy, building materials, coal preparation, and chemical industries. It can effectively prevent accidents caused by large and long ferrous pieces scratching conveyor belts, protecting crushers, grinders, and other mechanical equipment to operate safely and normally[^3^].Features and Advantages

• High magnetic field strength: The use of high-performance magnetic materials and optimized magnetic field structure improves magnetic field strength and uniformity, thus enhancing the iron removal effect.

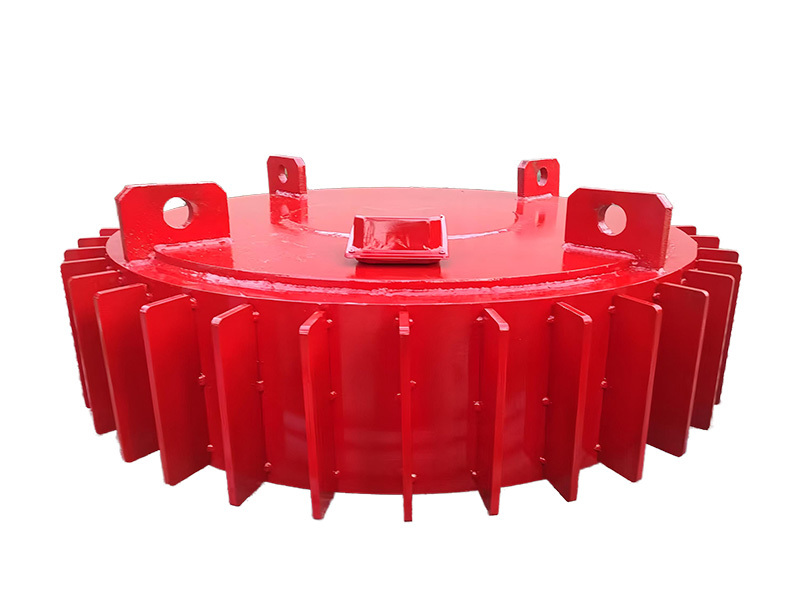

• Intelligent control: Some new electromagnetic separators integrate Internet of Things, big data, and artificial intelligence technologies to realize remote monitoring, automatic control, and intelligent adjustment functions.

• Environmentally friendly design: Focuses on energy saving and emission reduction and green production, using environmentally friendly materials and low-energy consumption designs to reduce energy consumption and environmental pollution.

Company Profile

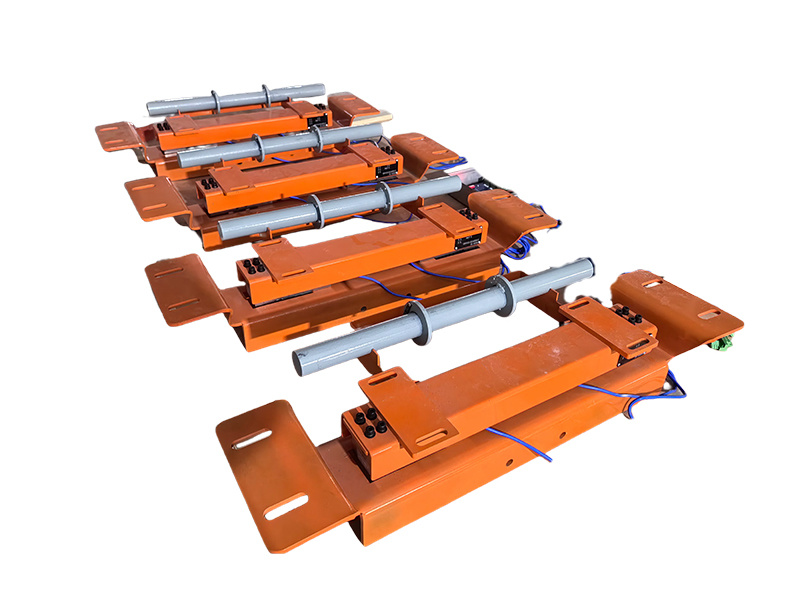

Business Scope:Conveyor, ration feeder, discharger, electromagnetic iron remover, belt scale, conveyor parts idlers, rollers, supports, ring conveyor belt.

Customization:Meet all your needs, no matter the size, even if you only have ideas, we will help you to achieve.

Применение

Автоматизированная фабрика

Сельскохозяйственная техника

Упаковочные машины

Логистическое оборудование

FAQ

Can I have my own custom product?

Yes. oem and odm can be provided, including design, logo, packaging, etc.

What is the minimum order quantity?

It depends on the product.

What are the terms of payment?

Wire transfer or letter of credit, Western Union, Alipay, etc.

When is the delivery time?

Inventory orders within 7-15 days, for oem and odm orders, the specific time depends on the actual situation.

Can I take samples for testing?

Yes, samples can be sent for testing before bulk ordering.

Do you have pre-shipment inspection procedures?

Yes, we always test the products before delivery.

Previous:

Electromagnetic iron remover

Still have questions? Please get a sample first.Contact us!

Classification

Keywords

Request a Quote

We will contact you within one working day. Please pay attention to your email.