- Description

-

A quantitative feeder is a material conveying device widely used in the industrial field, mainly used for the continuous weighing, metering, and quantitative conveying of solid bulk materials (such as blocky, granular, and powdery materials). Here is some key information about quantitative feeders:

Working Principle

Quantitative feeders control the amount of material conveyed by adjusting operating parameters (such as speed and material flow rate) to achieve precise material feeding. Its specific working principle includes:

• Control System: Equipped with an advanced control system, it adjusts operating parameters such as speed and material flow rate in real-time according to production needs to achieve precise feeding.

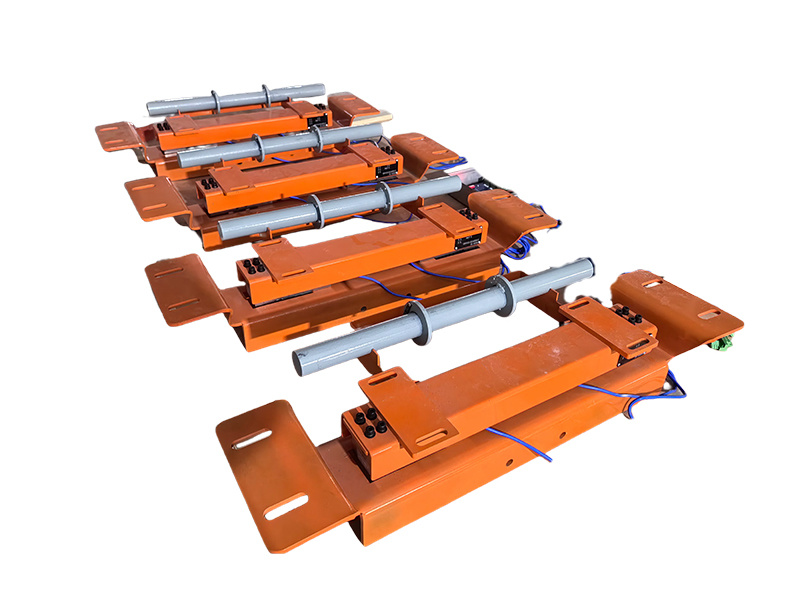

• Feeding Mechanism: Consists of a feeding mechanism and a transmission device. The feeding mechanism is the core component of material conveying, usually consisting of a screw conveyor or belt conveyor.

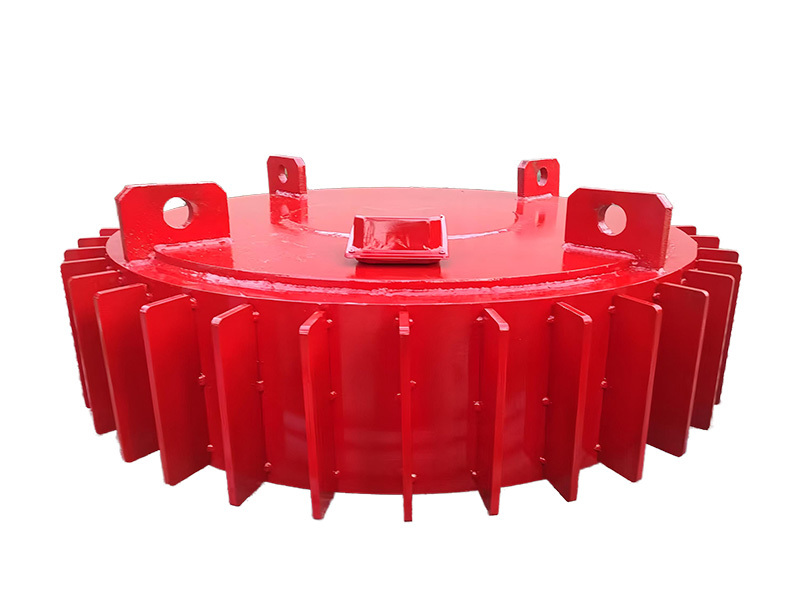

• Sensors: Equipped with weight sensors, flow sensors, etc., to monitor the weight or flow rate of the material in real-time and feed back to the control system to maintain stable material feeding.

Structural Features

Quantitative feeders have the following structural features:

• Simple Structure: Composed of weighing sensors, controllers, actuators, and inlets, it is easy to maintain and operate.

• High Accuracy: Using an advanced electronic metering system, it achieves high material metering accuracy, generally reaching ±1%.

• Convenient Adjustment: The control system uses a touch screen or computer control, with a user-friendly interface and simple parameter adjustment.

• Wide Range of Applications: Suitable for quantitative conveying of various powdery, granular, and blocky materials, such as cement, limestone, and slag.

• Energy-Saving and Environmentally Friendly: Achieving automated production, reducing manual operation errors, lowering energy consumption, and being environmentally friendly.

Applications

Quantitative feeders are widely used in the following fields:

• Building Materials Industry: Such as quantitative conveying of raw materials like cement and limestone.

• Chemical Industry: Such as quantitative conveying of fertilizers and chemical raw materials.

• Food Industry: Such as quantitative conveying of raw materials like milk powder and feed.

• Environmental Protection Industry: Such as quantitative conveying of solid waste in garbage and sludge treatment.

• Other Industries: Such as material conveying in mining and agriculture.

With its high efficiency, precise measurement, and wide range of applications, the quantitative feeder has become an indispensable piece of equipment in modern industrial production. With the development of technology and the improvement of intelligence, quantitative feeders will have broader application prospects in the future.

Company Profile

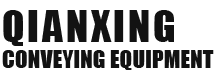

Business Scope:Conveyor, ration feeder, discharger, electromagnetic iron remover, belt scale, conveyor parts idlers, rollers, supports, ring conveyor belt.

Customization:Meet all your needs, no matter the size, even if you only have ideas, we will help you to achieve.

Применение

Автоматизированная фабрика

Сельскохозяйственная техника

Упаковочные машины

Логистическое оборудование

FAQ

Can I have my own custom product?

Yes. oem and odm can be provided, including design, logo, packaging, etc.

What is the minimum order quantity?

It depends on the product.

What are the terms of payment?

Wire transfer or letter of credit, Western Union, Alipay, etc.

When is the delivery time?

Inventory orders within 7-15 days, for oem and odm orders, the specific time depends on the actual situation.

Can I take samples for testing?

Yes, samples can be sent for testing before bulk ordering.

Do you have pre-shipment inspection procedures?

Yes, we always test the products before delivery.

Previous:

Next:

Quantitative feeder

Still have questions? Please get a sample first.Contact us!

Classification

Keywords

Request a Quote

We will contact you within one working day. Please pay attention to your email.