- Description

-

A belt scale is a device used for continuous dynamic measurement of the weight and flow rate of bulk materials being transported on a conveyor belt. Below is a detailed introduction to belt scales:

Working Principle

The working principle of a belt scale is based on Newton's second law of motion, which states that the acceleration of an object is directly proportional to the net force acting on it and inversely proportional to its mass. When material passes over the conveyor belt, the weight of the material exerts a downward force on the belt, while the belt exerts an upward supporting force on the material. By measuring the supporting force on the conveyor belt, the weight of the material can be determined.

The specific working process is as follows:

• Material enters the belt scale and is transported by the drive device.

• During the movement of the material, the weighing sensor measures the pressure or tension exerted by the material and transmits the signal to the control system.

• After receiving the signal from the weighing sensor, the control system performs calculations based on a preset algorithm to determine the weight of the material.

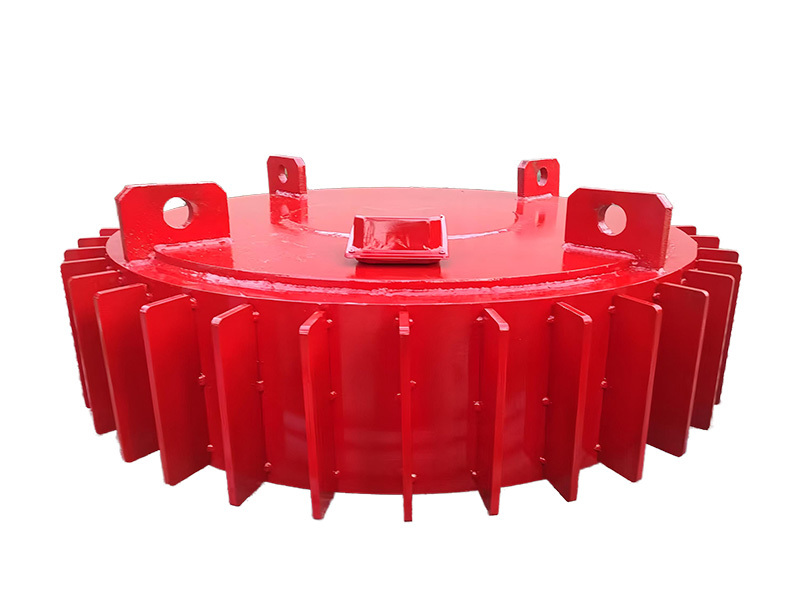

Components

A belt scale mainly consists of a weighing sensor, belt, belt support, drive device, and control system. The weighing sensor usually uses a pressure-type or tension-type weighing sensor to measure the weight of the material. The belt is the carrier for material transport, moving the material via the drive device. The belt support is used to support the belt and weighing system. The control system receives and processes signals from the weighing sensor to control and measure the material flow.

Applications

Belt scales are widely used in mining, power, chemical, and building materials industries, playing an important role in the accurate measurement of materials. It not only provides important parameters for production process control but also plays an important role in production batching. Specific application areas include:

• Mines and quarries: Measuring the weight of minerals, stones, etc., on the conveyor belt and monitoring their transportation.

• Coal mining, coal washing, etc.: Measuring and recording the weight of coal during the coal transportation process to provide data support for production management and measurement.

• Ports, docks, and logistics warehousing: Measuring and counting the weight of import and export goods, monitoring the flow and quantity of goods in the logistics process.

• Fertilizer, agricultural supplies production and circulation: Measuring the weight of bulk materials such as fertilizers and agricultural supplies during production and sales to ensure quality and accurate measurement.

• Cement, building materials, and furnace materials production: Measuring the weight of raw materials and finished products such as cement, building materials, and slag on the conveyor belt to monitor the production process and product quality.

• Food processing and grain storage and transportation: Measuring the weight of raw materials in food processing and the weight of grain during storage and transportation to ensure food safety and accurate grain measurement.

With its high efficiency and high precision, the belt scale is playing an increasingly important role in modern industrial production.

Company Profile

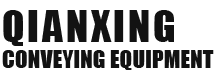

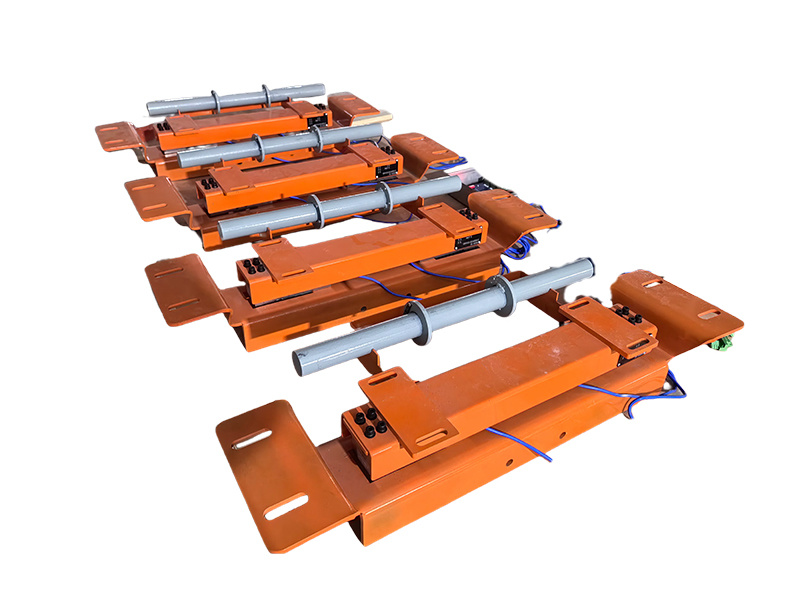

Business Scope:Conveyor, ration feeder, discharger, electromagnetic iron remover, belt scale, conveyor parts idlers, rollers, supports, ring conveyor belt.

Customization:Meet all your needs, no matter the size, even if you only have ideas, we will help you to achieve.

Применение

Автоматизированная фабрика

Сельскохозяйственная техника

Упаковочные машины

Логистическое оборудование

FAQ

Can I have my own custom product?

Yes. oem and odm can be provided, including design, logo, packaging, etc.

What is the minimum order quantity?

It depends on the product.

What are the terms of payment?

Wire transfer or letter of credit, Western Union, Alipay, etc.

When is the delivery time?

Inventory orders within 7-15 days, for oem and odm orders, the specific time depends on the actual situation.

Can I take samples for testing?

Yes, samples can be sent for testing before bulk ordering.

Do you have pre-shipment inspection procedures?

Yes, we always test the products before delivery.

Previous:

Electronic belt scale

Still have questions? Please get a sample first.Contact us!

Classification

Keywords

Request a Quote

We will contact you within one working day. Please pay attention to your email.